PRE-ENGINEERED BUILDINGS

REDUCED CONSTRUCTION TIME: Buildings are typically delivered in just a few weeks after approval of draw-ings. Foundation and anchor bolts are carted parallel and made ready for the site bolting. Our study shows that in India the use of PEB will reduce the total construction time of the project by at least 50%. This also allows faster occupancy and earlier realization of revenue.

| LOWER COST | Due to the systems approach, threre is a significant saving in design, manufacturing and on site erection cost.The secondary members and cladding new together reduces transportation cost. |

| FLEXIBILITY OF EXPANSION | Buildings can be easily expanded in length by adding additional hays. Also expansion in width and height is possible by pre designing for future expansion. |

| LARGE CLEAR SPANS | Buildings can be supplied to around 80M clear spans. |

| QUALITY CONTROL | As buildings are manufactured completely in the factory under controlled conditions the quality is assured. |

| LOW MAINTENANCE | Buildings are supplied with high quality paint systems for cladding and steel to suit ambient conditions at the site, which results in longer durability and low maintenance costs. |

| ENERGY EFFICIENT ROOFING & WALL SYSTEMS | Buildings can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required "U" values. |

| ARCHITECTURAL VERSATILITY | Buildings can be supplied with various types of fascias, canopies, and curved eaves and are designed to suit pre cast concrete wall panels, curtain walls, block walls and other wall systems. |

| SINGLE SOURCE RESPONSIBLITY | As the complete building package is supplied by a single vendor, the compatibility of all the building components and accessories is assured. This is one of the major benefits of the pre-engineered building systems. |

OUR PRE-ENGINEERED STEEL BUILDING CONSIST OF THE FOLLOWING

FRAMING SYSTEMS

PRODUCT DESCRIPTION

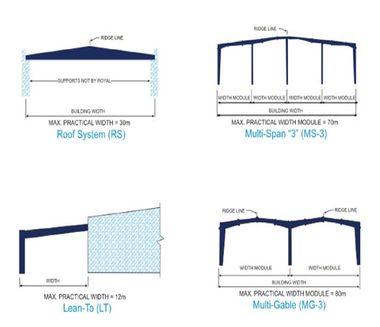

The most common primary framing system is shown. All shown systems are symmetrical about the ridge line. Framing systems unsymmetrical about the ridge line and Multi span framing systems with unequal width modules are also possible. Practically any frame geometry is possible. Contact us for your specific requirement. Our representative will always give you the right solution.

PRIMARY SYSTEMS

PRODUCT DESCRIPTION

Horizon Fabtech Infra Pvt Ltd pre-engineered buildings are custom-designed to meet your exact requirements. Practically any frame geometry is possible. Consult a Horizon Fabtech Infra Pvt Ltd representative for your specific requirements.

SECONDARY FRAMING

PRODUCT DESCRIPTION

Purlin, girt and eave struts shall be cold formed from steel which has minimum yields strength of 345 Mpa and will confirm to the physical specifications of ASTM A-570 (Grade 50) or equivalent. Z-SECTION. Purlins and Girts shall be roll formed Z-sections, 120-300 mm deep with 50-100 mm flanges. Each flange shall have a stiffening lip form with a thickness of 1.5 to 2.5 mm.C-channels are 100-300 mm deep roll formed with 50-100 mm Flanges with a thickness of 1.5 to 2.5 mm.All other miscellaneous secondary members shall have a minimum yield strength of 240 MPa.

ROOFING SHEETS

PRODUCT DESCRIPTION

Our Roofing Sheets are at par in excellence and are in conformation with the industry norms and standards. In this industry, we have marked an enviable reputation with our impeccable range of Roofing Sheets. We are technically very sound and try to inculcate all the developments in our product line so that our clients get the latest roofing sheet for their application. We also provide Clear Transparent as well as Translucent FRP / Polycarbonate Sheets matching our metal sheet profile.